Cressi-sub sets itself apart by being a company that is entirely controlled by one Italian family, the Cressi family. Since it was founded, to the present day, it has been built on a principle of not basing business on bank loans but on family money alone.

Contributed by

The classical philosophy of Italian diving

The huge mountain valley, the majestic bridges, the many cars and motorcycles, and people rushing to work are all first impressions of the industrial zone of Genoa. Here, we find the headquarters of the Cressi empire and their factory.

The Cressi trademark draws attention from afar, and the enormous building, located directly in the foothills, is impressive, with its hundreds of square meters of industrial workshops and many huge warehouses, nine meters high, well stocked with various sorts of techno polymers and boxes with finished products. In a three work shift cycle, the plant is kept in continuous operation around the clock producing, among other items, more than a million masks, making the Italian brand one of the most popular in the world, supplying snorkels for scuba divers and a hundred thousand of the most well-known models of Cressi fins.

The plant

The plant is virtually fully automated. Along the conveyor belt, robots seem to do everything. Computers are everywhere. Fins and masks are seen on the screens. The staff on duty have only to enter into the computer the type, the sizes and the colours of fins, masks or snorkels, to start the manufacturing process by simply pressing Enter on the keyboard.

We see how smart machines, not unlike giant vacuum cleaners, soak up polymer granules, which are heated up and melted into a liquid that is then filled into a pressing form. After cooling, the mould opens, and a robot moves the component onto the conveyor belt bringing it to the next process.

Every fin from Cressi-sub consists of three components, and consequently, it passes three sites on the conveyor belt. Thee-component fins have better characteristics and are more effective and durable than simpler and cheaper models.

The Cressi fins have variable elasticity depending on the direction and force applied to the blade. Underwater, it becomes visibly clear that Cressi’s fins are strong, elastic and have a powerful spring action. They are easy to use, even in strong currents, making them a real pleasure to wear. Snorkels and masks are manufactured in a similar manner. Pure liquid silicone (clear or black colour) is injected into a special mask mould under high pressure.

Every accessory for fins, snorkels and masks such as fasteners, straps, holders, glasses and other little items are also made here at this plant.

The most expensive components of this method of manufacture are the moulds of which there are several types and colours for the fins, masks, and snorkels respectively.

The quality, smoothness and functional characteristics of the items all depend on the quality of the mould. Therefore the creation of each mould from design to a finished model that it is good enough for production can easily run into the tens of thousands of dollars. This is an area where Cressi-sub excels.

The company has put huge capital investments, millions, into the manufacture and development of the top quality diving equipment. They take pride in being an entirely Italian manufacture and, as a symbol of quality and reliability, all Cressi-sub products come with a lifetime warranty.

Cressi history

Many of the old manufacturers have a company museum, but when you ask the question why Cressi doesn’t have one, the employees just shrug their shoulders. Their stance seems to be a practical one: “Here, we have spacious industrial workshops and the research laboratories are crammed with smart technology, the warehouses are full of raw materials and finished goods; offices with employees and a showroom with new product samples—in essence, everything that the strict laws of the effective manufacture require. But a museum, on the contrary, is just nostalgia and poetry that does not increase production speed.”

However, all the employees, from the bottom up, feel like they belong to one big Cressi family and take pride in the fact that the company has already existed for almost 60 years. Everyone seems to be quite familiar with the key moments of the family and company history.

In the beginning

It all began as far back as 1940, when Egidio Cressi developed, in his home, the first mask, called Sirena. Then in the following years, from 1941-1945, the two Cressi brothers, Egidio, who was the diver of the pair, and Nanni, who was the business representative (and the father of today’s “boss”, Antonio Leopoldo Cressi) began the production of underwater equipment in their home.

In 1946, the business extended into the establishment of the company Il Pescatore Subacqueo Cressi, later to be renamed Cressi-sub Spa. It is a little known fact that in 1947, the company created their first rebreather called ARO 47.

For some reason this and some of the other activities in the postwar years seem to be kept a family secret, although the developments of rebreathers apparently continued. The ARO 57B was later introduced in 1956. Also in 1947, we saw the first full face masks, the Medusa G1 and G2, with integrated snorkels. The next significant step came in 1951 when the first modern fin, the Rondine, came to light. It was the first fin with an inclined blade and an open foot-pocket.

At that time, the project manager at Cressi was Luigi Ferraro, who later went on to found Techni-sub, another one of the big old dive equipment manufacturers. Also, at this same time, a former officer in the Austrian army, Ludwig Mares, came to the Rapallo to open a little shop, and later to found the Mares company.

In 1953, the first mask with optical lenses and a nose within the skirt was introduced. This was the Pinocchio, which is still in production today in more modernized forms.

In the middle of the 1960’s, the company created their first regulator and then decided to go into the creation and production of a full line of diving equipment including masks, fins, snorkels, neoprene suits, regulators, rebreathers, cylinders, knifes, spear guns, harpoons and torches.

For the first time, a diver had the choice and the opportunity to be equipped totally with Cressi-sub equipment from top to toe. And as time has later shown, this was a good idea. In 1970, Cressi also made a splash when they marketed, as one of the first, a BCD that had an inflator hose connected to the first stage.

Cressi’s history can be characterized as one of creative work, new ideas and experiments all aimed at the development and popularization of scuba diving. Persistence, enthusiasm, belief in correctness and passionate desire to make the world’s best diving equipment have occupied the minds of the Cressi family throughout their company history.

Cressi-sub today

The many current successes of the company can be attributed mainly to one person, Mr. Antonio Cressi, who has headed the company for two decades. Mastering all the stages of manufacturing, logistics, sales and business management, he can be said to have graduated from the manufacturing floor. He is not hiding in a fancy office either, as a business executive would often do, but leads, as an expert, where all the action is.

In the early morning, it is possible to meet him practically in any of the production “hot” spots: at the conveyor-belt, in a warehouse, at the workshop where the suits are manufactured, in the shipping department or at orders and deliveries.

Without any much ado, he warmly greets the employees as he makes his rounds of the factory, dynamically solving questions and giving necessary instructions on the fly.

The factory now has 16,000 square meters covered with sophisticated robotic production systems, and their highly specialized R&D department is equipped with the latest computers and testing equipment.

Nonetheless, like his father before, Antonio believes that any new product, even if designed by today’s computers, must pass the test of extensive use in the sea before it qualifies to carry the name of which he is so proud. “Do not drop the majestic name of Cressi,” is the motto and philosophy of the company.

Today the company is recognized as one of the global leaders in dive equipment design from masks, fins and snorkels to suits. Cressi-sub has also just opened a completely new venue in the production of dive masks. Only safe non-allergenic silicone is used. It is profoundly changing the quality of sealing, new shapes of masks, glasses, frames and even the snorkel-holders.

The use of new technologies has allowed Cressi to combine three types of materials in one product and to make new composite types of fins, which among other things are about 30 % lighter, than the competitor’s models, yet they pack a powerful stroke and offer less resistance in the water. Cressi fins are created especially for the ocean, for diving and swimming in currents with less fatigue. They do indeed stand out with their ideal shapes, magnificent design, surfaces as smooth as mirrors, faultless quality and a lifetime guarantee. These are the fins of the new century, and they are technological marvels.

No right to make mistakes

Cressi-sub, being one of the world’s largest private dive equipment manufacturers, also has a high influence on diving fashion. But how are decisions made as regards to which models and what equipment will appear on the diving market? What are the secrets behind Cressi’s successes?

Luca Falko, from Cressi’s export department explains:

“Cressi is a family business, and if our company is going to start production of some new dive equipment, we want to be absolutely sure that we get a positive result. We should be certain that our innovations will be well received by divers, and here again, quality equipment should be irreproachable, it should have great looks and faultless long-term quality. A private company, such as Cressi-sub, does not have any right to make mistakes. New samples of equipment are tested thoroughly, sometimes for months or even years. All products, regardless of being tested rigorously by machines or on special equipment, will also be tested personally by the boss. Mr. Antonio Cressi wants to be absolutely sure that the quality, reliability, convenience, stylishness and operation of the equipment are flawless for all types of diving.

“The next very important aspect of our philosophy has to do with the opinion and responses to the use of our equipment by world famous people. So, Hollywood stars Chuck Norris and Pierce Brosnan, dive with Cressi-sub. National Geographic teams use Cressi-sub equipment in their projects. Free diving world champions, Umberto Pelizzari and Deborah Andollo, have all chosen Cressi-sub. This also contributes to the basis of the family business, which is determining the success for our company.”

Future Cressi

Millions of people in the world go to the seaside for recreation. Consequently a mask, fins and a snorkel are already an integral part of equipment for many a holiday-maker. Diving with a complete set of ABC equipment is the first step into the underwater world and a way to introduce the wider audience to scuba diving. And here, Cressi-sub is an undisputed global market leader. As the number of holidaymakers and active divers worldwide seem to grow from year to year, Cressi’s future seems to be quite bright.

For more information, please visit: www.cressi-sub.it

Published in

-

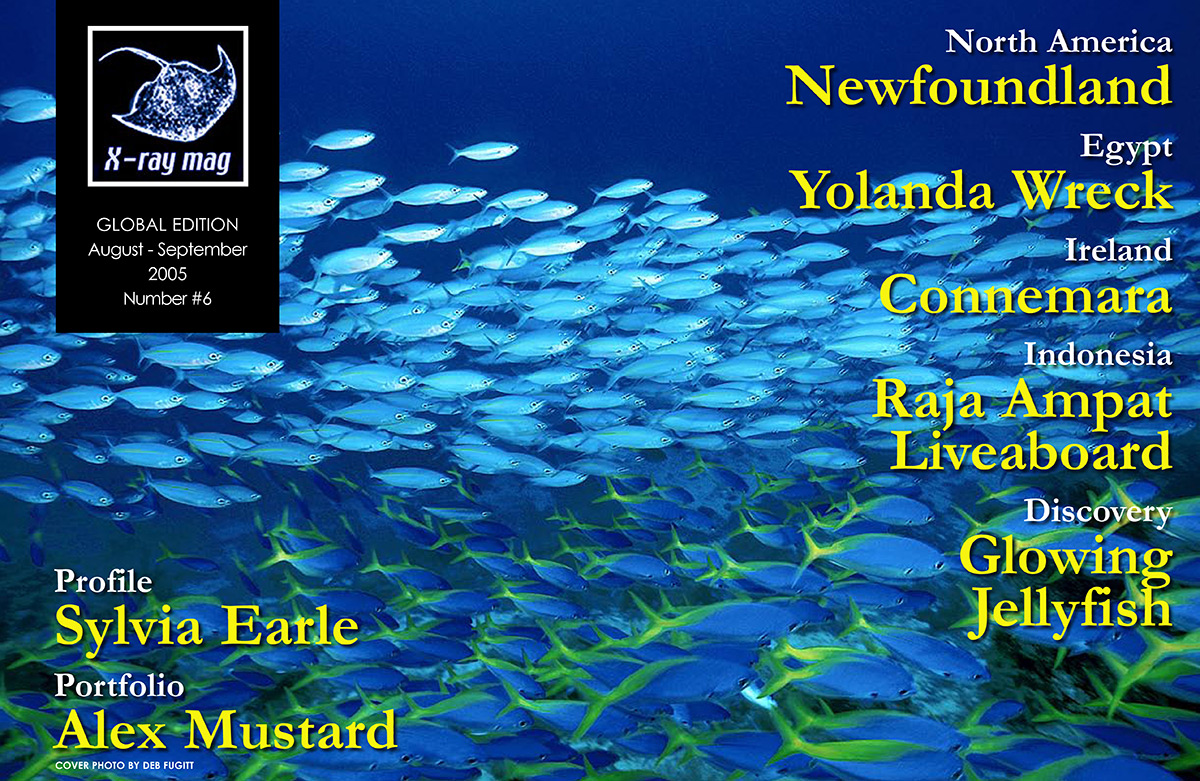

X-Ray Mag #6

- Read more about X-Ray Mag #6

- Log in to post comments